Speedy Component Replacement

By:

Al

Klase

The

obvious way

to

replace a leaded component, such as a capacitor, is to

“excavate” the

two

solder joints using a solder sucker and various tools to clear the

solder

and unwrap the wire leads from the terminal. Unfortunately,

this

is not only time consuming, but is also likely to result in an

unsightly

mess if not actual damage to irreplaceable parts. All too

often

the

component being replaced was the first one wrapped around the

terminal.

Even if the repairman exercises extreme care, the original

craftsmanship

is destroyed.

|

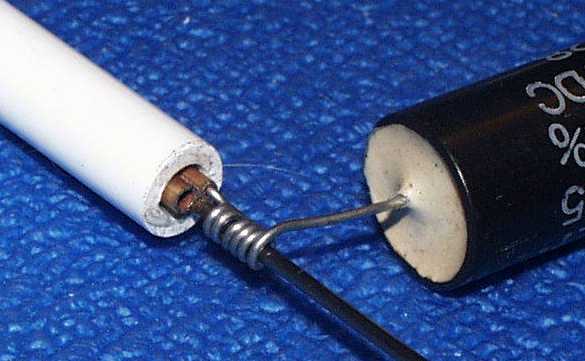

An

answer

to this

problem comes to us from the 1950’s. Sprague

capacitors, packaged

for replacement service, came with devices called quigs.

These

were

small spirals of wire heavily coated with solder and flux.

The

recommended

procedure was to cut the leads of the old components leaving a generous

stub. The new cap was then sleeved onto the old leads with

the

quigs.

A brief application of the soldering iron completed the job.

Quigs

are

now vanishingly

rare, but a similar technique can still be used. Cut the

leads of

the old part near the component body. Twist tight

“pigtails” in

the

leads of the new device. Thread these over the old wires, and

solder

in the usual manner.

|

|

|

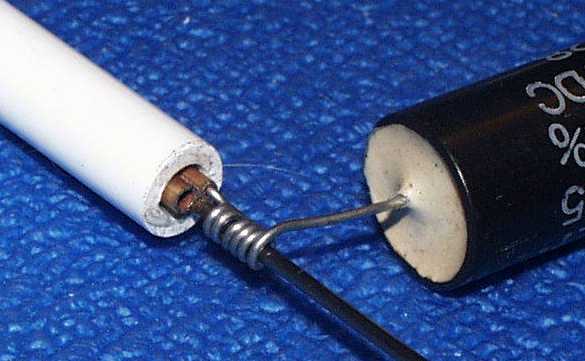

A

convenient tool

for forming the “pigtails” can be fashioned from

common hobby-shop

materials.

It consists of two short lengths of brass tubing, 1/16” and

3/32”

diameter,

soldered to a length of 0.040” music wire, and glued into a

handle made

of thick-walled 5/16” plastic tubing. When the end

of a component

lead is inserted into the brass tube, a neat spiral can be quickly

formed.

|

Another

alternative

is a stiff piece of wire or drill rod held in a pin vice.

With

luck,

the collet will have sufficient open space to insert the end of the

lead.

This

technique

allows

a capacitor to be replaced in just a minute or two, even if its buried

deeply in the chassis. (This is a real boon when doing a

Hallicrafters

SX-28!) The results are tidy and preserve the original

craftsmanship

of the radio.